Category: Press Release

Trillium Renewable Chemicals Selects INEOS Green Lake for World’s First Demonstration Plant for Sustainable Acrylonitrile Production

Posted on

KNOXVILLE, Tenn. (June 4, 2024) — Trillium Renewable Chemicals (Trillium) (www.trilliumchemicals.com) today announced the selection of INEOS Nitriles’ Green Lake facility in Port Lavaca, Texas (ineos.com) to establish the world’s first demonstration plant for converting plant-based glycerol into acrylonitrile. The demonstration plant is named “Project Falcon.”

Trillium Renewable Chemicals has developed a groundbreaking technology for producing sustainable acrylonitrile, a key raw material in numerous industries, including toys, auto parts, aerospace components, medical supplies, and apparel. Selecting INEOS – the world’s leading global manufacturer of petrochemicals, underscores Trillium’s ambition to scale up its technology in an industrial environment to accelerate progress.

“Trillium is thrilled that INEOS Nitriles Green Lake, home to America’s largest acrylonitrile production plant, will serve as the home for Project Falcon,” said Corey Tyree, CEO of Trillium Renewable Chemicals. “This milestone is a significant step forwards in bringing our technology to market and producing sustainable bio-based acrylonitrile at scale.”

Following a $10.6M Series A financing round in December 2022 and $2.5 million award from the Department of Energy’s Advanced Manufacturing Office in June 2022, Trillium constructed a pilot plant that successfully produced acrylonitrile from glycerol. Trillium’s sustainable acrylonitrile offers a lower carbon footprint than standard acrylonitrile based on the Sohio propylene process. The company’s innovative approach addresses growing customer demand for greener bio based raw materials.

Trillium continues to operate a pilot plant and has successfully provided samples to customers. Pilot operations also have contributed valuable insights for the design of the Falcon plant, which will be operated at the INEOS Nitriles Green Lake site.

Hans Casier, CEO of INEOS Nitriles, highlighted the significance of Trillium’s decision,” INEOS Nitriles is very pleased to be working with Trillium to advance technology for the production of sustainable bio-based acrylonitrile. Our support of this project, which is part of our wider sustainability strategy, emphasises our commitment as the world’s largest producer of acrylonitrile, to reducing the carbon footprint of the industry. We look forward to working closely with Trillium to help achieve this objective.”

The operation of Project Falcon will help to validate commercial-scale economics and product carbon footprint at scale. Emphasis will be placed on achieving process performance criteria such as plant uptime, demonstrating key equipment in its final form, and securing qualification as a supplier of bio-based acrylonitrile. Set to commence operations in early 2025, the project will run through early 2026.

For more information on Trillium Renewable Chemicals and Project Falcon, please visit www.trilliumchemicals.com.

Media Contact:

Trillium: Elena Brennan | 865-329-0553 | elena@piper-communications.com

INEOS: Richard Longden | +41 799 626 123 | Richard.longden@ineos.com

About Trillium Renewable Chemicals

Trillium is replacing oil and gas with plant-based feedstocks in the manufacturing of green, drop-in molecules. Trillium has developed proprietary thermochemical technology to convert plant-based feedstocks like glycerol into valuable chemical intermediates (acrylonitrile and acetonitrile). Acrylonitrile is used to manufacture a wide range of materials (e.g., acrylonitrile-butadiene-styrene (ABS) plastic, carbon fiber, acrylic fiber, nitrile butadiene rubber (NBR), acrylamide, specialty amines). As the worldwide demand for these chemicals increases, Trillium is providing a green alternative. Learn more at www.trilliumchemicals.com.

About INEOS

A global petrochemicals manufacturer, INEOS operates 194 sites across 29 countries, generates $65 billion annually* and employs over 26,000 people. Complementing our core business, INEOS is making an impact across a range of elite sports and becoming increasingly known to consumers with the launch of the Grenadier (our uncompromising 4×4) and INEOS Hygienics. More than 90% of Acrylonitrile produced globally uses INEOS Technology. Our leadership in this product is based on our technological know-how and manufacturing capability. The chances are that acrylonitrile touches everyone in some way, every day. It is the key ingredient in Acrylic Fibre used to make clothing and carpet. ABS (Acrylonitrile-butadiene-styrene), a durable thermoplastic, is used in Automobile Components, Telephones, Computer Casings and Sports Equipment. Nitrile Rubber has many applications and is used to manufacture a multitude of products including hoses for pumping fuel and products used across healthcare applications such as PPE.

Trillium Announces Partnership with Zeton to Design Sustainable Acrylonitrile Demonstration Plant

Posted on

Successful pilot program advances Trillium to the next step in commercialization, the design of a Market Demonstration Plant

KNOXVILLE, Tenn. – Trillium Renewable Chemicals (Trillium) (www.trilliumchemicals.com) announced today its partnership with Zeton to design the world’s first demonstration plant to convert plant-based glycerol into acrylonitrile, deemed “Project Falcon.”

Trillium is pioneering the development of a new chemical manufacturing process to produce acrylonitrile from glycerol. Zeton is the world leader in the design and fabrication of demonstration plants and small modular production plants. The Trillium-Zeton partnership kicks off the design phase of Project Falcon, which paves the way for low-carbon footprint apparel, toys, cars, medical gloves, planes, and many more products.

Following a $10.6M Series A financing round in December 2022 and $2.5 million award from the Department of Energy’s Advanced Manufacturing Office in June 2022, Trillium successfully built a pilot plant that produced acrylonitrile from glycerol. Trillium’s pilot plant continues to operate and will provide product samples to customers for validation. Information collected during these pilot trials will be used to design the Falcon plant.

“We are thrilled to partner with Zeton in the next stage of our commercialization journey,” said Erik Scher, Trillium’s newly-appointed Board Chair. “Demonstrating Trillium’s technology at a larger scale will allow our customers to verify product quality at scale, a key milestone in our path to becoming a leading producer of renewable chemicals .”

“With its breakthrough glycerol to acrylonitrile technology, Trillium is leading the way in sustainable chemicals manufacture,” said Dr. Leisl Dukhedin-Lalla, President and CEO of Zeton, Inc. “Zeton is proud to have been chosen by Trillium to design the Falcon plant, and is looking forward to accelerating the commercialization of this technology by delivering this landmark project.”

Operation of Project Falcon will be used to verify process economics and product carbon footprint at large scale. New focus will be given to achieving operational performance criteria (e.g., plant uptime), demonstration of key equipment in final form, and successful qualification as a supplier of acrylonitrile.

Media Contacts

Elena Brennan

+1 (865) 329-0553

elena@piper-communications.com

David Edwards

+1 (905) 632-3123

Follow Trillium on LinkedIn

Follow Trillium on X @TrilliumChem

ABOUT TRILLIUM RENEWABLE CHEMICALS

Trillium is replacing oil and gas with plant-based feedstocks in the manufacturing of green, drop-in molecules. Trillium has developed proprietary thermochemical technology to convert plant-based feedstocks like glycerol into valuable chemical intermediates (acrylonitrile and acetonitrile). Acrylonitrile is used to manufacture a wide-range of materials (e.g., acrylonitrile-butadiene-styrene (ABS) plastic, carbon fiber, acrylic fiber, nitrile butadiene rubber (NBR), acrylamide, specialty amines). As the worldwide demand for these chemicals increase, Trillium is providing a green alternative. Learn more at www.trilliumchemicals.com

ABOUT ZETON

ZETON is a recognized world leader in the design and fabrication of lab scale systems, pilot plants, demonstration plants and small modular commercial plants using modular fabrication. The company serves a wide range of industries and applications including oil & gas, polymers, chemicals, synfuels and alternative energy, bioenergy and biofuels, pharma and biotech, mining and hydromet, fine chemicals, environmental and sustainable chemistry. Process modules are engineered and fabricated at ZETON’s two state-of-the-art, integrated design-build facilities in Oakville, Ontario, Canada and Enschede, The Netherlands. They can be shipped virtually anywhere in the world for field installation.

Trillium Announces Close of Series A Financing, Raising $10.6 Million

Posted on

New investment round led by Hyosung and HELM AG will accelerate the commercialization of Trillium’s process to manufacture chemicals from plant-based materials.

Knoxville, December 5, 2022

Trillium Renewable Chemicals (www.trilliumchemicals.com) announced today it has raised a $10.6M Series A financing round. The first closing totaled $5.5M and was led by Hyosung Advanced Materials Corporation. Current investor Capricorn Partners also participated. HELM AG has agreed to join the Series A round to bring the total to $10.6M. This funding builds on the company’s non-dilutive award of $2.5M from the US Department of Energy. Following a successful pilot program, the funding advances Trillium to the next phase of commercialization – the construction and operation of a market demonstration unit.

Trillium’s innovative Bio-ACN™ process sustainably converts plant-based feedstocks into valuable chemicals like acrylonitrile and acetonitrile. Acrylonitrile is currently manufactured from oil and gas derivatives to make a diverse range of consumer and industrial goods including carbon fiber, plastic, textiles, flocculant, synthetic rubber, and other valuable materials. These materials are used in finished products such as apparel, auto parts, aerospace parts, medical gloves, toys, consumer electronics, personal care products, sporting goods, and water treatment chemicals.

Young Joon Lee, Vice President at Hyosung, said: “We are excited to be a partner with TRC for this innovative technology development and the commercialization pathway. Sustainability is at the heart of Hyosung’s future growth strategy, and we firmly believe that our strong partnership will take us to the next level of industry leadership in renewable chemicals space.”

Andreas Woschek, Executive Vice President at HELM AG, said: “HELM is highly committed to grow its chemical business via sustainable solutions. Our engagement in Trillium marks another milestone in delivering tangible actions via our sustainability strategy. The combined skillsets of the partners supporting Trillium now provides an exciting opportunity to commercialize the innovation of bio-based, low carbon Acrylonitrile to the market.”

“Demonstrating our technology at scale is job one,” said Corey Tyree, CEO of Trillium. “Financial backing from HELM AG and Hyosung advances Trillium to demonstration scale. The addition of strategic investors also validates our technology and our potential. With funding from quality partners, we can realize our potential to become a leading producer of renewable chemicals.”

Rob van der Meij and Wouter van de Putte from the Capricorn Sustainable Chemistry Fund, managed by Capricorn Partners, and Board Member of Trillium added: “It is great to have such constructive co investors that bring significant value to the company for the scale up and market introduction.”

Media Relations

Elena Brennan

+1 (865) 329-0553

elena@piper-communications.com

Janneke Menzel

+49 (40) 2375 1855

janneke.menzel@helmag.com

Ju Han Lee

+82 (2) 707-7650

juhan@hyosung.com

Follow us on Twitter @TrilliumChem

ABOUT TRILLIUM RENEWABLE CHEMICALS

Trillium is replacing oil and gas with plant-based feedstocks in the manufacturing of green, drop-in molecules. Trillium has developed proprietary thermochemical technology to convert plant-based feedstocks like glycerol into valuable chemical intermediates (acrylonitrile and acetonitrile). Acrylonitrile is used to manufacture a wide-range of materials (e.g., acrylonitrilebutadiene-styrene (ABS) plastic, carbon fiber, acrylic fiber, nitrile butadiene rubber (NBR), acrylamide, specialty amines). As the worldwide demand for these chemicals increase, Trillium is providing a green alternative. Learn more at www.trilliumchemicals.com

ABOUT HYOSUNG ADVANCED MATERIALS

Founded in 1968, Hyosung Advanced Materials Corporation (HAMC), is the global no. 1 polyester tire reinforcements company with an annual revenue of 4B USD. HAMC’s business covers industrial material of various applications that serve a variety of industries. In response to the transition of the mobility industry and the need for green technology, HAMC continues to develop and commercialize high-strength and light-weight materials that contribute to less product carbon emissions. Learn more at www.hyosungadvancedmaterials.com

ABOUT HELM AG

HELM is a Hamburg, Germany, based family-owned company established in 1900. HELM is one of the world’s largest chemicals marketing companies and committed to providing solutions to its partners that support a successful transformation to a sustainable economy and society. The company secures access to the world’s key markets through its specific regional knowledge and its multinational presence in more than 30 countries. As a multifunctional marketing organization HELM is active in the chemicals industry, in the agricultural industry and in pharmaceuticals, generating global revenues of EUR 6 billion per year. Learn more at www.helmag.com

ABOUT CAPRICORN PARTNERS

Capricorn Partners, an independent Leuven (Belgium) based manager of venture capital and equity funds, invests in innovative companies with technology as a competitive advantage. It operates under an AIFM license granted by the FSMA (the Financial Services and Markets Authority in Belgium). The investment in Trillium is made from the Capricorn Sustainable Chemistry Fund. Learn more at www.capricorn.be

Trillium awarded DOE funding for biobased acrylonitrile demonstration plant

Posted on

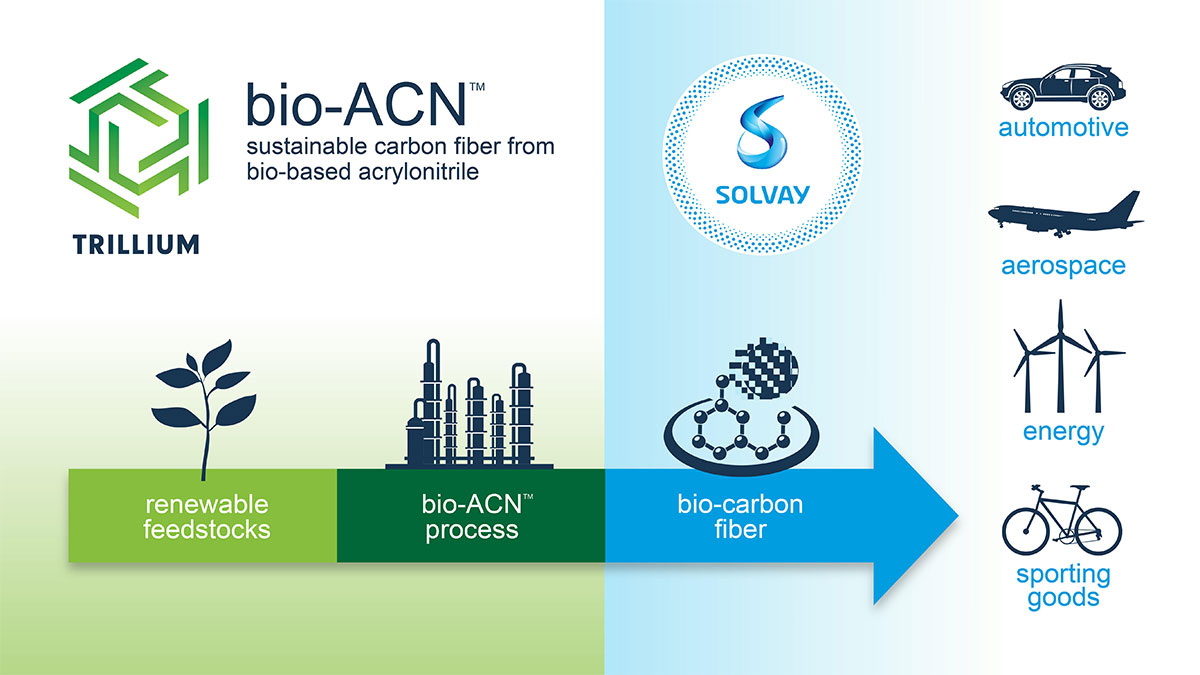

New award will enable Trillium and its project partners (Solvay, Koch Modular, MATRIC) to demonstrate sustainable production of acrylonitrile at scale.

Knoxville, December 5, 2022

Trillium Renewable Chemicals has been selected by the Department of Energy’s Advanced Manufacturing Office to receive $2.5 million to accelerate commercialization of Trillium’s process to manufacture bio-based acrylonitrile product. Trillium and its development partner (MATRIC) are currently operating a pilot plant in Charleston, West Virginia. This nondilutive funding, in combination with Trillium’s recent Series A closing of $10.6M, provides funding to Trillium and MATRIC to design, build, and operate a market demonstration unit – the next step in Trillium’s commercialization plan. Trillium will provide product to Solvay for validation of the product for use in manufacturing of carbon fiber. Solvay will also perform an independent ISO 9001 lifecycle analysis of Trillium’s product. Koch Modular will provide a front-end loading engineering design of a first commercial plant.

Acrylonitrile is a chemical intermediate typically made from petroleum-based feedstocks like propylene and is a key raw material used in the production of carbon fiber, acrylic fiber, acrylamide, ABS plastic, nitrile butadiene rubber, and other valuable products. Trillium’s BioACN™ process delivers acrylonitrile from plant-based feedstocks like glycerol with a lower carbon footprint. By starting with biobased raw materials, Trillium’s product offers the potential to decarbonize a wide range of industrial and consumer products.

“Demonstration of the Bio-ACN™ process at larger scale is an exciting next step,” explains Corey Tyree, CEO of Trillium. “Thanks to the Department of Energy, this project brings together participants across the supply chain to accelerate progress by supporting our next major commercial milestone. The unit will produce the volumes needed to qualify as a supplier. And it will provide the information we need to further de-risk and design a commercial plant. Trillium is proud to be amongst the awardees.”

Media Relations

Corey Tyree

+1 (205) 757-5938

ctyree@trilliumchemicals.com

Elena Brennan

+1 (865) 329-0553

elena@piper-communications.com

Follow us on Twitter @TrilliumChem

ABOUT TRILLIUM RENEWABLE CHEMICALS

Trillium is replacing oil and gas with plant-based feedstocks in the manufacturing of green,

drop-in molecules. Trillium has developed proprietary thermochemical technology to

convert plant-based feedstocks like glycerol into valuable chemical intermediates

(acrylonitrile and acetonitrile). Acrylonitrile is used to manufacture a wide-range of

materials (e.g., acrylonitrile-butadiene-styrene (ABS) plastic, carbon fiber, acrylic fiber,

nitrile butadiene rubber (NBR), acrylamide, specialty amines). As the worldwide demand for

these chemicals increase, Trillium is providing a green alternative. Learn more at

www.trilliumchemicals.com

Solvay to Collaborate with Trillium on Bio-based Acrylonitrile for Carbon Fiber Applications

Posted on

Solvay and Trillium Renewable Chemicals have signed a letter of intent to develop the supply chain for bio-based acrylonitrile (bio-ACN). Trillium will supply Solvay with bio-ACN from Trillium’s planned commercial asset, and Solvay will evaluate bio-ACN for carbon fiber manufacturing as part of its long-term commitment to developing sustainable solutions from bio-based or recycled sources. The aim of this partnership is to produce carbon fiber for use in various applications such as aerospace, automotive, energy, and consumer goods.

Acrylonitrile is a chemical intermediate typically made from petroleum-based feedstocks like propylene and is the primary raw material used in the production of carbon fiber. Trillium’s Bio-ACNTM process delivers acrylonitrile from plant-based feedstocks like glycerol with a lower carbon footprint.

“We are thrilled to be partnering with Trillium which aligns well with our Solvay One Planet commitment to more than double our revenue based on renewable or recycled materials by 2030,” comments Stephen Heinz, head of composite research & innovation, Solvay. “Innovation partnerships such as this are driven by a desire to make a real-world sustainability impact. Bio-based feedstocks are a key part of Solvay’s sustainability strategy, and we look forward to being a consumer of bio-ACN from Trillium’s first bio-based acrylonitrile plant.”

“Trillium’s bio-ACN process technology enables bio-carbon fiber,” explains Corey Tyree, CEO of Trillium. “We are excited to continue our partnership with Solvay, who have supported the bio-ACN process technology development since 2014. Solvay is a leader in the most rapidly-growing acrylonitrile segment (carbon fiber) and we are market leaders in bio-carbon fiber and sustainable development.”

Trillium Renewable Chemicals media contact

Corey Tyree

Chief Executive Officer

ctyree@trilliumchemicals.com

About Trillium Renewable Chemicals

Trillium is replacing oil and gas with plant-based feedstocks in the manufacturing of green, drop-in molecules. Trillium has developed proprietary thermochemical technology to convert plant-based feedstocks like glycerol into valuable chemical intermediates (acrylonitrile and acetonitrile). Acrylonitrile is used to manufacture a wide-range of materials (e.g., acrylonitrile-butadiene-styrene (ABS) plastic, carbon fiber, acrylic fiber, nitrile butadiene rubber (NBR), acrylamide, specialty amines). These materials have a wide range of end uses including aerospace, automotive, apparel, toys, energy, personal care products, pharmaceuticals, consumer electronics, and wastewater treatment. As the worldwide demand for these chemicals increases, Trillium is providing a green alternative that reduces carbon emissions, improves safety, and offers customers competitive economics. Learn more at www.trilliumchemicals.com.

About Solvay

Solvay is a science company whose technologies bring benefits to many aspects of daily life. With more than 23,000 employees in 64 countries, Solvay bonds people, ideas and elements to reinvent progress. The Group seeks to create sustainable shared value for all, notably through its Solvay One Planet roadmap crafted around three pillars: protecting the climate, preserving resources and fostering a better life. The Group’s innovative solutions contribute to safer, cleaner, and more sustainable products found in homes, food and consumer goods, planes, cars, batteries, smart devices, health care applications, water and air purification systems. Founded in 1863, Solvay today ranks among the world’s top three companies for the vast majority of its activities and delivered net sales of €9 billion in 2020. Solvay is listed on Euronext Brussels and Paris (SOLB). Learn more at www.solvay.com.

Capricorn Partners and Southern Research Create Trillium Renewable Chemicals

Posted on

Today the majority of the more than 350,000 chemical products in circulation are made from oil or natural gas. But bolstered by scientific advances, changing consumer preferences, and regulatory pressures, a growing number of chemicals will be made from renewable feedstocks in the future.

Trillium Renewable Chemicals is poised to address this fast-growing market segment through commercialization of the technology invented by Southern Research. The technology converts renewable feedstocks, such as sugar or glycerol to chemical products like acrylonitrile, propylene glycol, and acrylic acid. These products are currently manufactured from oil and gas and used to make many familiar consumer and industrial goods like clothing, toys, car parts, sporting goods, paints, soaps, and other valuable materials.

“Southern Research is excited to team up with Capricorn Partners to further the development of our patented technology,” said Michael Catalano, Chief Operating Officer for Southern Research. “With the foundation of Trillium and focused management, we will be able to maximize the commercial potential, which is the ultimate goal and in-line with our strategy to monetize intellectual property for re-investment in future scientific endeavors.”

Trillium and Southern Research will continue to work jointly on the process development, while Trillium will team up with strategic partners for the scale up and deployment of the technology.

Corey Tyree, CEO of Trillium Renewable Chemicals: “Trillium will demonstrate the commerciality of this technology. Local production from renewable resources can meet the growing demand for green chemicals and offer stable pricing and a more secure supply chain. The market interest is there. To address it, the industry needs enabling technologies such as the catalyst discovered by Southern Research.”

Amit Goyal, lead inventor from Southern Research: “The Southern Research team developed an innovative, elegant thermo-catalytic process that utilizes biomass derived sugars or glycerol, allowing for the use of a variety of biomass feedstocks, to produce acrylonitrile and other co-products. This process has the potential to improve economics and the overall environmental footprint of downstream products that utilize acrylonitrile as a raw material.”

Capricorn Partners has invested from its Capricorn Sustainable Chemistry Fund. The proceeds will be used to scale up the process for the manufacturing of acrylonitrile and glycols. Wouter Van de Putte and Rob van der Meij, of Capricorn Partners: “We spotted the Southern Research Technology over 2 years ago and have been following the development closely as well as exploring market opportunities in Europe and the USA. This type of ‘green drop-in” molecule technology has a great advantage over new ‘green’ molecule developments in that the applications are already fully developed.”

The Capricorn Sustainable Chemistry Fund, with a committed capital of € 86.5 million, is aiming to capture the growing opportunities emerging from novel feedstocks, innovative and sustainable processes, more performing functional materials, and smarter use of precious raw materials. Capricorn invests in companies which combine sound financial returns with a material contribution to and a front-runner view on developments in sustainability and advanced materials, processes, and products. The fund focuses on companies that are in or near revenue stage and provided that the technologies and products are disruptive and have the potential to significantly address global markets.

Trillium Renewable Chemicals media contact

Corey Tyree

Chief Executive Officer

ctyree@trilliumchemicals.com

About Trillium Renewable Chemicals

Trillium is replacing oil and gas with plant-based feedstocks in the manufacturing of green, drop-in molecules. Trillium has developed proprietary thermochemical technology to convert plant-based feedstocks like glycerol into valuable chemical intermediates (acrylonitrile and acetonitrile). Acrylonitrile is used to manufacture a wide-range of materials (e.g., acrylonitrile-butadiene-styrene (ABS) plastic, carbon fiber, acrylic fiber, nitrile butadiene rubber (NBR), acrylamide, specialty amines). These materials have a wide range of end uses including aerospace, automotive, apparel, toys, energy, personal care products, pharmaceuticals, consumer electronics, and wastewater treatment. As the worldwide demand for these chemicals increases, Trillium is providing a green alternative that reduces carbon emissions, improves safety, and offers customers competitive economics. Learn more at www.trilliumchemicals.com.

About Capricorn Partners

Capricorn Partners is an independent European manager of venture capital and equity funds, investing in innovative European companies with technology as competitive advantage. The investment team of Capricorn is composed of experienced investment managers with deep technology expertise and a broad industrial experience. Capricorn Partners is managing the venture capital funds Capricorn Sustainable Chemistry Fund, Capricorn Digital Growth Fund, Capricorn ICT Arkiv, Capricorn Health‐tech Fund and Capricorn Cleantech Fund. In addition, it is the management company of Quest for Growth, quoted on NYSE Euronext Brussels, and the investment manager of Quest Cleantech Fund and Quest+, sub‐funds of Quest Management SICAV, registered in Luxembourg. Find more information at www.capricorn.be.

About Southern Research

Southern Research (SR) is an independent, 501(c)(3) nonprofit, scientific research organization with more than 400 scientists and engineers working across three divisions: Life Science (Drug Discovery & Development), Engineering, and Energy & Environment. SR supports related industries with independent research on behalf of commercial and government clients, objectively assessing new technologies and providing process development support. SR also pursues entrepreneurial and collaborative initiatives to develop and maintain a pipeline of intellectual property and innovative technologies that positively impact real-world problems. SR is headquartered in Birmingham, Alabama with additional laboratories and offices in Frederick, Maryland and Houston, TX. Find more information about SR at https://southernresearch.org.